|

| August 14, 2012 | Volume 08 Issue 30 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

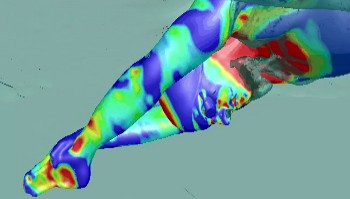

Swimwear simulation helps increase speed, win gold

Virtual prototyping reduces the need for real-world testing. Competitive swimmers this summer have been streamlining performance thanks to Speedo's revolutionary Fastskin Racing System, which was designed using engineering simulation software from ANSYS. When worn together as a complete system, a Fastskin suit, cap, and goggle can reduce full-body passive drag by up to 16.6%, improve oxygen economy by up to 11% (enabling the athlete to swim stronger for longer), and reduce active body drag by up to 5.2%.

"Engineering simulation has been absolutely critical in launching this world-first concept," said Tom Waller, head of Speedo's in-house global research and development facility, Aqualab. "For the first time, competitive swimmers can use a cohesive, hydrodynamic solution that will help them cut through the water with maximum efficiency. In developing the Fastskin Racing System, ANSYS software gave us the confidence that our designs would perform as expected in the real world - and saved us a huge amount of resources that we would otherwise have had to invest in physical testing."

In engineering the three components into a system, Aqualab used data from more than 1,200 separate simulations conducted with ANSYS multiphysics software. By replicating the dynamic pressures of competitive swimming in a risk-free virtual design environment, these simulations helped engineers to minimize the effects of turbulence and drag, mitigate the impact force generated by a dive, maximize the structural strength of the goggle assembly, and address other real-world design concerns.

Following the design work, Speedo conducted a number of pool tests of the new racing system using professional athletes, including Natalie Coughlin, Ryan Lochte, and Michael Phelps of the United States.

While Speedo is a long-time ANSYS customer, development of the racing system relied on an expanded, multiphysics perspective that included both fluid dynamics and structural mechanics analyses. For the goggles, for example, ANSYS solutions offered insight about the structural forces that impact the equipment from all directions, which lightweight material would be able to withstand those forces, and how the shape generated turbulence that could negatively impact the swimmer's downstream performance. This broader approach matches the new, forward-looking portfolio of products that Speedo is developing to meet swimmers' full-body needs.

"ANSYS has a long history of working with leading organizations to produce winning products - whether it be a swimsuit that helps to shave fractions of a second off an elite athlete's performance or a hybrid vehicle battery that delivers optimal value in terms of cost, reliability, energy usage, and safety," said Jim Cashman, president and CEO of ANSYS.

The Fastskin Racing System comprises a choice of products, including caps, goggles, and suits, that allow swimmers to select the best combination to meet their preferences and performance needs. Improvement to passive drag affects the swimmer during the submerged, glide phase of any stroke, which is particularly important after the start and at each turn. Oxygen economy relates to the swimmer's efficiency and his consumption of oxygen during the activity. Active drag (or surface drag) affects the swimmer at the surface during the active swimming phase of any stroke. It results from the waves that the swimmer creates, the swimmer's constantly changing shape and the force of the water passing over the body's surface.

Source: ANSYS

Published August 2012

Rate this article

View our terms of use and privacy policy